Maharashtra 401 405, India

10, CFC Tower, Happinest Phase

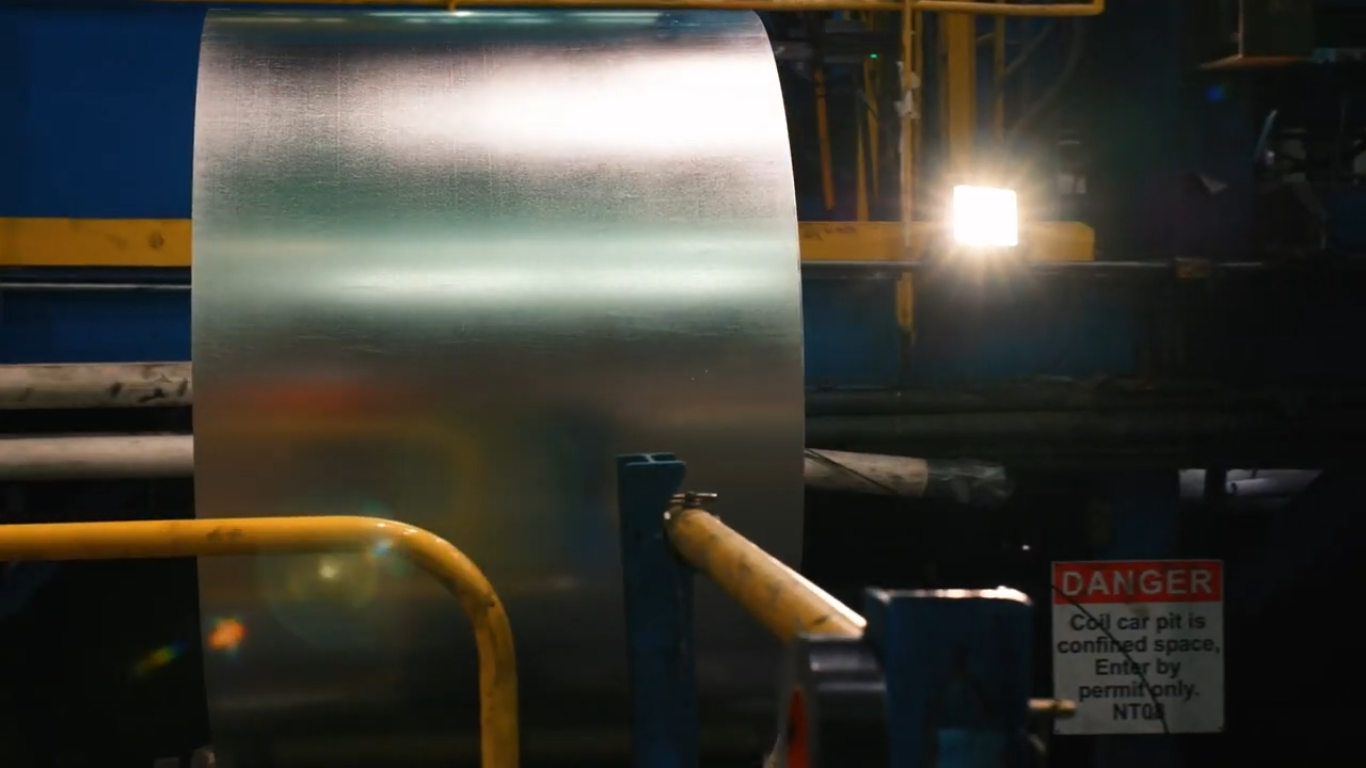

At SHRINIDHI ISPAT, our Galvanize/Galvalume Steel Plant is a testament to our dedication to providing durable and corrosion-resistant steel products. Equipped with cutting-edge technology and operated by a team of experienced professionals, our plant delivers consistent and high-quality coated steel.

- Our pre-treatment section ensures thorough cleaning and preparation of the steel substrate, optimizing coating adhesion.

- Our state-of-the-art hot-dip line applies a uniform and durable coating of zinc (galvanized) or zinc-aluminum alloy (galvalume) to the steel.

- We employ a high-speed continuous hot-dip galvanizing line, designed for maximum throughput and consistent coating performance

- Our controlled cooling and solidification process ensures optimal coating adhesion and uniformity.

- The water spray rapid cooling system is integrated with our automated control system, ensuring precise cooling rates and optimal coating properties.

- Our skin pass/tension leveling process improves the flatness and surface finish of the coated steel

- A chemical passivation process is applied to enhance the corrosion resistance of the coated steel

- We implement stringent quality control measures throughout the entire coating process, including:

Coating thickness measurement

Adhesion testing

Surface inspection

Chemical composition analysis of the coating

- Our plant is capable of producing a diverse range of galvanized and galvalume steel products, including coils and sheets, in various thicknesses, widths, and coating weights, to meet the specific needs of our customers.

| Product | Thickness (mm) | Width (mm) | Length (mm) | Coil Weight | Coating Mass |

| Galvanized Steel Coils | 0.25 – 2.5 | 50 to 1550 | N/A | Max. 25 Tons | Zn80 - Zn275 gsm* |

| Galvanized Steel Sheets | 0.25 – 2.5 | Up to 1550 | up to 12000 | N/A | Zn80 - Zn275 gsm* |

| Galvalume Steel Coils | 0.25 – 1.2 | 50 to 1250 | N/A | Max. 25 Tons | AZ 40 - AZ 200 gsm |

| Galvalume Steel Sheets | 0.25 – 1.2 | Up to 1250 | Up to 12000 | N/A | AZ 40 - AZ 200 gsm |

Zn= Zinc | AZ= AluZinc |*Can be extended up to 400 gsm

Surface: Regular Spangle, Minimized Spangle

Surface Type: Skin-pass/ Non-skin-pass as per requirement

Surface Treatment: Chrome 3/ Chrome 6/ Chrome-freepassivation/ oiled/ unoiled

Galvanized and Galvalume steel are both popular choices for applications requiring corrosion resistance, but they achieve this through slightly different coating compositions. Here's a breakdown of their advantages:

- The zinc coating acts as a "sacrificial anode," meaning it corrodes before the underlying steel. This provides excellent protection, even if the coating is scratched.

- Generally, galvanized steel is more economical than Galvalume.

- Galvanized steel performs well in environments with high humidity and is generally better suited for contact with concrete and mortar

- Galvanizing is a well-established and widely used process, making galvanized steel readily available.

- Galvalume, with its aluminum-zinc alloy coating, offers significantly better long-term corrosion resistance than galvanized steel in most atmospheric conditions.

- Galvalume is very good in rainy climates.

- Galvalume typically has a longer service life, especially in outdoor applications.

- The aluminum in the Galvalume coating provides excellent heat reflectivity, which can help reduce energy costs in buildings

- Galvalume often has a smoother, more uniform appearance than galvanized steel.

- Galvalume has self healing properties at cut edges.

- Galvanized: Primarily zinc.

- Galvalume: Aluminum-zinc alloy

- Galvalume excels in most outdoor environments, while galvanized performs well in specific conditions.

- Galvanized is typically cheaper, but Galvalume offers a longer lifespan

In essence, the choice between galvanized and Galvalume steel depends on the specific application, environmental conditions, and budget considerations.

Galvanized and Galvalume steel sheets, coils, and strips are incredibly versatile due to their corrosion resistance and are used across a wide range of industries. Here's a detailed breakdown of their applications: