Maharashtra 401 405, India

10, CFC Tower, Happinest Phase

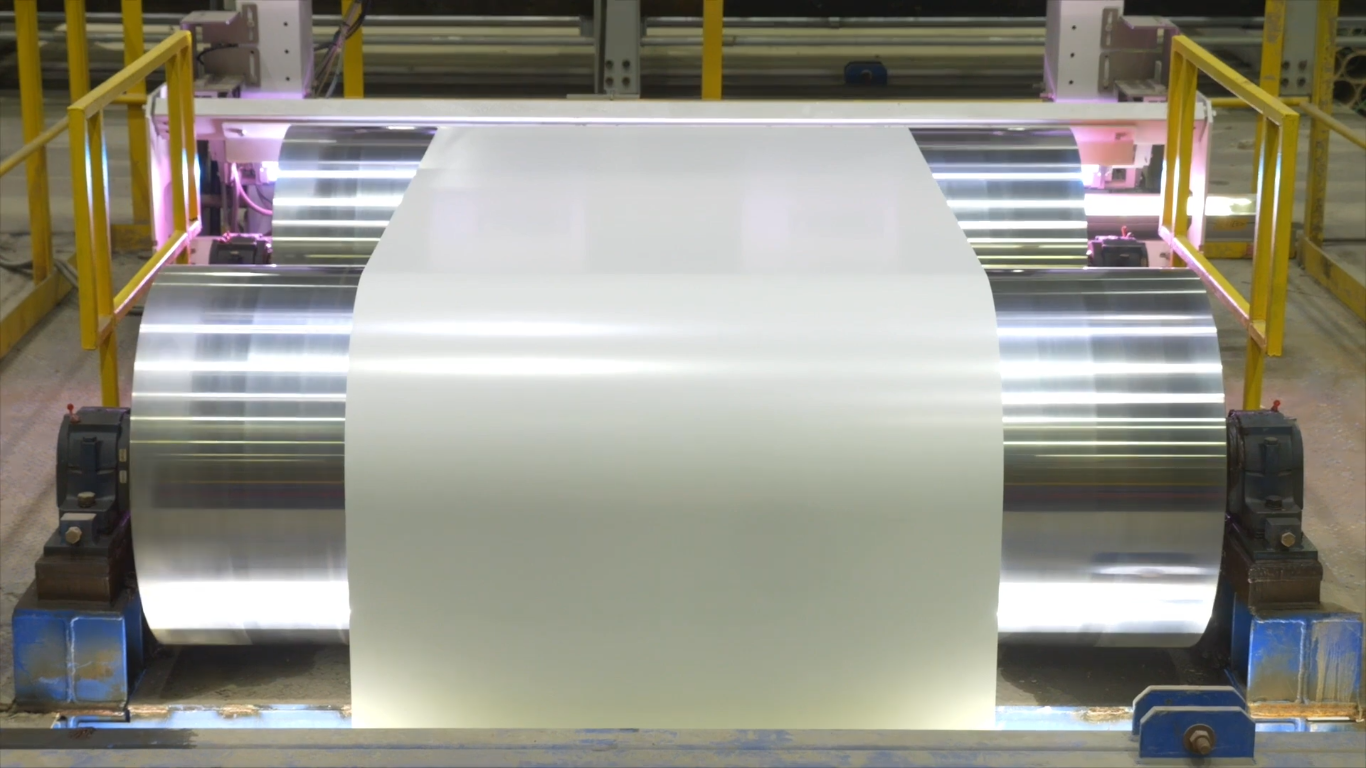

At SHRINIDHI ISPAT, our Pre-painted Galvanized/Galvalume steel facility is a state-of-the-art operation designed to deliver high-quality, durable, and aesthetically pleasing coated steel products. We combine the corrosion protection of galvanized or Galvalume steel with the versatility and visual appeal of pre-painted finishes.

- Our facility includes a comprehensive cleaning and pre-treatment line to ensure optimal adhesion of the paint coating. This includes degreasing, chemical pre-treatment, and rinsing stages.

- We utilize modern coil coating technology to apply uniform and consistent paint coatings.

- Our coatings include a range of high-performance paints, such as:

Regular Modified Polyester (RMP):

- Colour Coated Steel painted and dried with polyester

- Offers excellent workability, weather resistance, and durability. 1

-Provides a wide range of colors and brightness, suitable for interior and exterior construction materials, assembling metals, and partitions.

- Substrates: GI, GL.

- Applications: Lightweight partitions, steel furniture, roofing, siding, and sandwich panels.

Silicon Modified Polyester (SMP):

- Silicon Modified Polyester (SMP):

- Offers superior weather resistance, providing better protection than RMP in construction applications.

- Substrates: GI/GL.

- Substrates: GI/GL.

Super Durable Polyester (SDP):

- Pre-finished steel suitable for construction materials.

- High workability, brightness, clearness, and printing features, ideal for construction and metal devices requiring these qualities.

- Substrates: GI/GL.

- Applications: Exterior metal devices and roofing.

Polyvinylidene Fluoride (PVDF):

- Steel sheets applied and hardened with fluorine resin paint, known for its symmetric structure and inert fluorine content.

- Steel sheets applied and hardened with fluorine resin paint, known for its symmetric structure and inert fluorine content.

- Substrates: GI/GL.

- Applications: Metal exteriors, sandwich panels, and structures in industrial complexes.

Controlled Curing Ovens :

- Our curing ovens maintain precise temperature control to ensure proper curing and bonding of the paint coating.

Quality Control and Testing :

- We implement rigorous quality control measures throughout the entire process, including:

Coating thickness measurement.

Coating thickness measurement.

Adhesion testing.

Flexibility and impact resistance testing.

Salt spray testing.

| Properties | Standard / Test Method | Results |

| Specular Gloss | EN 13523-2 [2001] | 50 - 60 |

| Pencil Hardness | EN 13523-4 [2001] | H - 2H |

| Resistance to Rapid Deformation (Impact Test) | EN 13523-5 [2014] | 100KG - CM |

| Adhesion after Indentation (Cupping Test) | EN 13523-6 [2002] | > 6.5mm |

| Resistance to Cracking on Bending (T-bend Test) | EN 13523-7 [2014] | > 1T |

| Scratch Resistance | EN 13523-12 [20117] | > 1.5KG |

| Resisitance to Salt Spray (fog) | EN 13523-8 [20117] IS14246 [2013] Class-1 and Class-2 | > 600 hrs |

| Resisitance to Fluorescent UV Light and Water Condensation | ASTM D2244 | Moderate |

Wide Range of Colors and Finishes :

- We offer a wide selection of colors, finishes, and textures to meet diverse customer requirements.

Versatile Product Range :

- Our facility produces pre-painted galvanized and Galvalume steel coils and sheets in various thicknesses and widths.

| Thickness | 0.3 - 1.5mm Total Coated Thickness |

| Width | PPGI - Up to 1550mm; PPGL= up to 1250mm |

| Zn Coating | 80 - 275 g/m2 |

| Al-Zn Coating | 150 - 200 g/m2 |

| Color | all RAL Colors, or according to customer’s requirements |

| Paint System | RMP, SMP, SDP & PVDF |

| Top Side | Primer paint + polyester paint coating (25 microns) min |

| Back side | Primer epoxy (10 microns) min |

| Coil Weight | 3-8 tons per coil |

| Salt Spray Resistance | >=1000 hours with SDP /PVDF Paints. |

| SRI Value | > = 80 (Subject to Shade Specific) |

PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) coils, strips, and sheets offer significant advantages over traditional uncoated or post-painted steel. Here's a breakdown of the key benefits:

- PPGI: The galvanized substrate provides excellent sacrificial protection against rust.

- PPGL: The Galvalume substrate offers superior long-term corrosion resistance, especially in harsh environments.

- The pre-painted layer further enhances this protection, creating a multi-layered barrier against moisture and chemicals.

- The combination of the metallic coating (galvanized or Galvalume) and the paint layer significantly extends the lifespan of the steel.

- These products are designed to withstand harsh weather conditions, including rain, snow, sunlight, and temperature fluctuations.

- Pre-painted steel offers a wide range of colors, finishes, and textures, allowing for greater design flexibility.

- Consistent color application ensures a uniform and aesthetically pleasing appearance.

- Custom colors and finishes can be readily produced to meet specific project requirements.

- Pre-painting at the factory eliminates the need for on-site painting, reducing labor costs and time.

- Pre-painting at the factory eliminates the need for on-site painting, reducing labor costs and time.

- Reduced waste compared to post painting.

- Modern coil coating processes ensure that the paint layer is flexible and adheres well to the steel substrate, allowing for forming and fabrication without cracking or peeling.

- This makes PPGI/PPGL suitable for a wide range of forming operations, including bending, rolling, and stamping.

- Factory-controlled coating processes ensure consistent quality and finish across the entire product.

- This eliminates the variations and imperfections that can occur with on-site painting.

- Factory coating processes are more environmentally friendly than on-site painting, as they minimize the release of volatile organic compounds (VOCs).

- The long lifespan of PPGI/PPGL reduces the need for frequent replacements, conserving resources.

- Galvalume's aluminum component provides excellent heat reflectivity, which can help reduce energy consumption in buildings, especially in hot climates.

PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) coils, strips, and sheets are highly versatile materials with a wide range of applications across various industries. Here's a detailed breakdown:

- Residential, commercial, and industrial buildings.

- Corrugated roofing, standing seam roofing, and tile roofing.

- Wall panels, facades, and insulated panels.

- Purlins, girts, and framing systems.

- Metal building systems and pre-engineered buildings.

- Metal building systems and pre-engineered buildings.

- Ceiling systems, partition walls, and interior paneling.

- Cleanroom panels and modular construction.

- Ductwork, air handling units, and ventilation systems.

- Refrigerators, washing machines, dryers, and ovens.

- Water heaters, air conditioners, and other HVAC appliances.

- Structural supports and components within appliances.

- Truck and trailer bodies, bus panels, and recreational vehicles.

- Trim panels, dashboards, and structural supports.

- Toolboxes, storage units, and protective covers.

- Warehouses, factories, and storage facilities.

- Metal containers, storage boxes, and industrial packaging.

- Control panels, switchgear, and equipment housings.

- Reflectors, housings, and lighting components.

- Barns, sheds, and storage buildings.

- Grain bins, silos, and livestock shelters.

- Components of farm machinery and equipment.

- Cabinets, shelving, and storage units

- Display racks, shelving, and signage.

- Structural supports and mounting systems.

- Outdoor signs, billboards, and advertising displays.

- Shipping containers.