Maharashtra 401 405, India

10, CFC Tower, Happinest Phase

Material: Low-carbon steel wire

Diameter: Ø 0.40 mm – Ø 16 mm

Coating: Hot-Dipped Galvanized (Zn)

Coating Thickness: 40-350 g/m²

Tensile Strength: 350-500 N/mm², 500-700 N/mm²,700-900 N/mm²

Coil Weight: up to 1200 kg (or as per customer’s requirement.)

Standard: EN 10244-2:2023

Applications: Production of wire netting, barbed wires, security panels, PVC coated wires, wire meshes,Cages, bucket handles and nails.

Material: Low-carbon steel wire

Diameter: Ø 0.80 mm – Ø 8 mm

Coating: Hot-Dipped Galvanized (Zn)

Coating Thickness: 112-350 g/m²

Tensile Strength: 350-500 N/mm², 650-850 N/mm²,850-1050 N/mm²

Coil Weight: up to 1200 kg (or as per customer’s requirement.)

Standard: EN 10257-2:2011 / EN 10244-2:2023

Applications: Power cables, Subsea cables, Umbilical cables.

Material: Low-carbon steel wire

Diameter: Ø 0.80 mm – Ø 8 mm

Coating: Zn-90% Al-10% & Zn-95% Al-5% (Galfan)

Coating Thickness: 40 – 300 gr/m2

Tensile Strength: 350-500 N/mm2, 500-700 N/mm2,700-900 N/mm2

Coil Weight: up to 1200 kg (or as per customer’s requirement.)

Standard: EN 10244-2:2023

Applications: Production of Gabion, wire netting, barbed wires, security panels, Honeycomb wire meshes, cages, etc.

Material: High-carbon steel wire

Diameter: Ø 1.40 mm – Ø 6.50 mm

Coating: Hot-dip galvanized (Zn)

Coating Thickness: 180 – 350 gr/m2

Tensile Strength: 850-2050 N/mm²

Coil Weight: 750 - 1250 kg (or as per customer’s requirement.)

Standard: EN 10244-2:2023

Applications: Production of steel ropes and cord wires.

Material: High/Low-carbon steel wire

Diameter: Ø 0.75 mm – Ø 10 mm

Tensile Strength: 500-1900 N/mm²

Coil Weight: 750 - 2000 kg (or as per customer’s requirement.)

Applications: Production of nails, staples, meshes, etc.

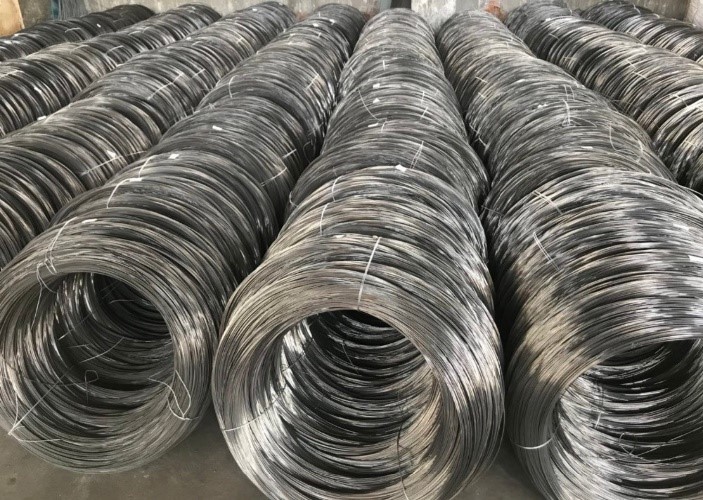

Material: Annealed wire

Diameter: Ø 0.90 mm – Ø 8 mm

Diameter: Ø 0.90 mm – Ø 8 mm

Tensile Strength: Max. 450 N/mm²

Coil Weight: up to 2000 kg (or as per customer’s requirement.)

Applications: The construction industry, etc.

Material: Low-carbon cold drawn bright wire

Diameter: Ø 1.80 mm – Ø 8 mm

Surface Treatment: A light coating of black soot.

Tensile Strength: 550-750 N/mm²

Coil Weight: up to 1000 kg (or as per customer’s requirement.)

Applications: In production of metal baskets, shelves, etc.

Material: Low/ Medium/ High-carbon Hot Rolled Billets

Diameter: Ø 5.2 mm – Ø 22 mm

Coil Weight: up to 2600 kg (or as per customer’s requirement.)

Applications: Industrial wires, Fasteners, Chain rivet wires,Tyre reinforcement, springs, Wire mesh, Pre- Stressed Concrete, Vineyard wires,Automobile components, Wire ropes, etc.

Long steel products find diverse applications across various sectors, playing a crucial role in modern infrastructure and industrial development. Here are some key areas where they are extensively used:

This list highlights some of the major applications of long steel products. Their versatility, high strength, and durability make them indispensable in modern society, contributing to the development and advancement of various industries.